Tricot – the history

The world Tricot comes from the French Language. It means knit, in fact it is used to cover everything related to the knitting process in order to create a fabric. Its origins of tricot seems to go back to the IV century a.c. where in ancient Greece a fabric very similar to modern tricot was used to make ceremonial dresses.

The Modern Era

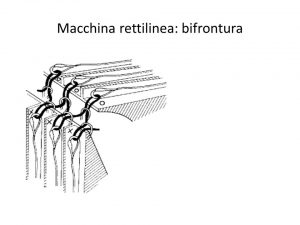

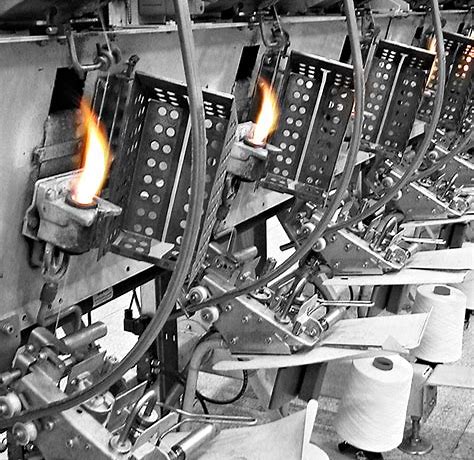

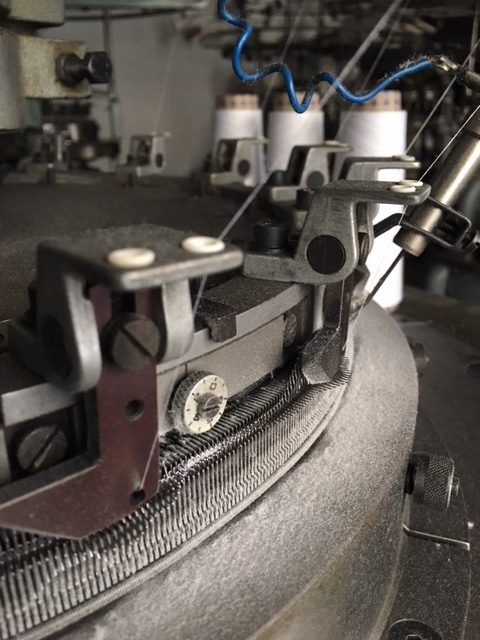

With coming of the industrial revolution in the middle of the 800’s, machines were built, doing work that before it was possible to do only by hand. The knitted fabric once hand made with the classic iron needles, now was produced by flat knitting machines which were hand operated. (see picture)

Subsequently with the second industrial revolution, the driving force changed from hand power to steam and then finally electricity. Conceptually, the tricot machines remained the same, with the same working concept, but the productive capacity increased considerably. In fact, in order keep up with the new requests from an evergrowing market the production volume was significanty increased. Nowdays, most of the mechanical parts of the flat knitting machine, have been substituted with electronics, following modern tendencies and using new Technologies. This allows for a larger variety of designs also more precision.

Above all one of the best charteristics of the flat knitting machine is the possibility to change pattern mid production; consequently, the wristbands and waistband are ribbed and exactly as in the jumpers there are no seams, this makes our tricot garments more comfortable and luxurious.

Charateristics of tricot

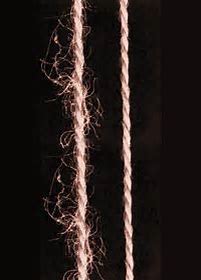

Furthermore, this type of knitting has a very good elasticity also body, when Merino wool is used, the fabric become soft and heavy, giving a great protection against the cold.

Some of our tricot products

More Info

(Lowlands)

(Lowlands) (Giza 45)

(Giza 45)

(John Mercer)

(John Mercer)

(A. Volta)

(A. Volta)

(Coco Chanel)

(Coco Chanel)